Pick side - straight or tilted

Straight pick side

Use a straight pick side for unloading (picking) complete boxes and bins.

Or use a straight pick side when picking is done out of the front of the box or bin.

Or use a straight pick side when you can create enough picking space between the levels.

In general, any depth of a box or bin is acceptable for a straight pick side.

Tilted pick side

A tilted picking tray gives a larger opening for picking.

This is ideal for order picking single articles out of the box or bin.

This easier access to a box or bin can also be used to build in an extra level.

There will be less space between the levels, but it is still possible to pick from the box or bin through a tilted position.

With a tilted pick side, the box or bin depth is limited to a maximum of 600 mm.

Misunderstanding

Existing installations with a tilted pick side have often an interesting phenomenon:

The first (lowest) level comes with a straight pick side.

Big disadvantage: The opening for picking is a lot smaller than for the other levels. A straight pick side under a tilted pick side always gives the smallest opening for picking. This slows down the order picking cycle and is frustrating for the order picker.

The reason for this is often the designer’s ignorance or the covering up of the loss of storage height through the so called “bent” flow racks (these give a lot of loss in height at the 1st level).

Flowrack knows how it’s done

Using a clever design, we create a tilted pick side without any disadvantages.

Our advice: Always use a tilted pick side for all levels.

Your specific situation

We would like to advise you on what would be most useful in your situation.

Please contact us for more information.

Examples

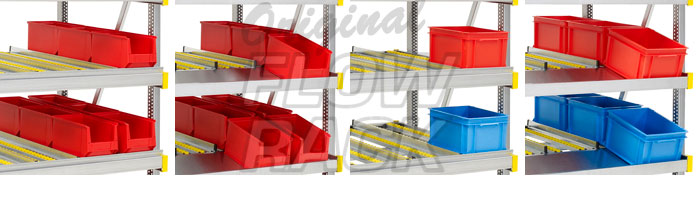

Example with bins 200x300 mm and 300x400 mm:

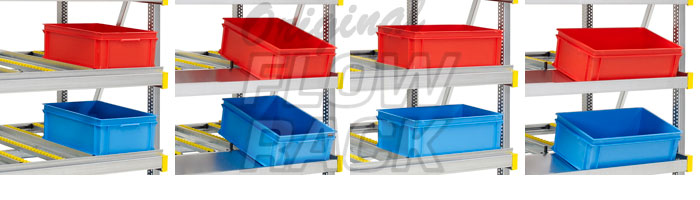

Example with bins 400x600 mm, set “along” as well as “across”:

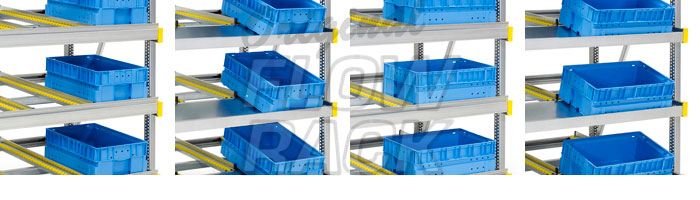

Example with KLT/VDA bins 400x600 mm, set “along” as well as “across”:

Example with CBL crates 400x600 mm, set “along” as well as “across”: